Extraction System | Supercritical CO₂ | Hydrodistillation | Microwave | Ultrasound | Enzyme-Assisted

Reducing energy consumption during hydrodistillation—commonly used to extract essential oils from aromatic plants like Aquilaria, Cinnamomum, Cananga, etc.—is crucial for sustainable processing, especially in rural or off-grid settings.

Strategies, technologies, and process innovations to optimize hydrodistillation with reduced energy usage, without compromising oil yield or quality:

Energy-Efficient Hydrodistillation Strategies

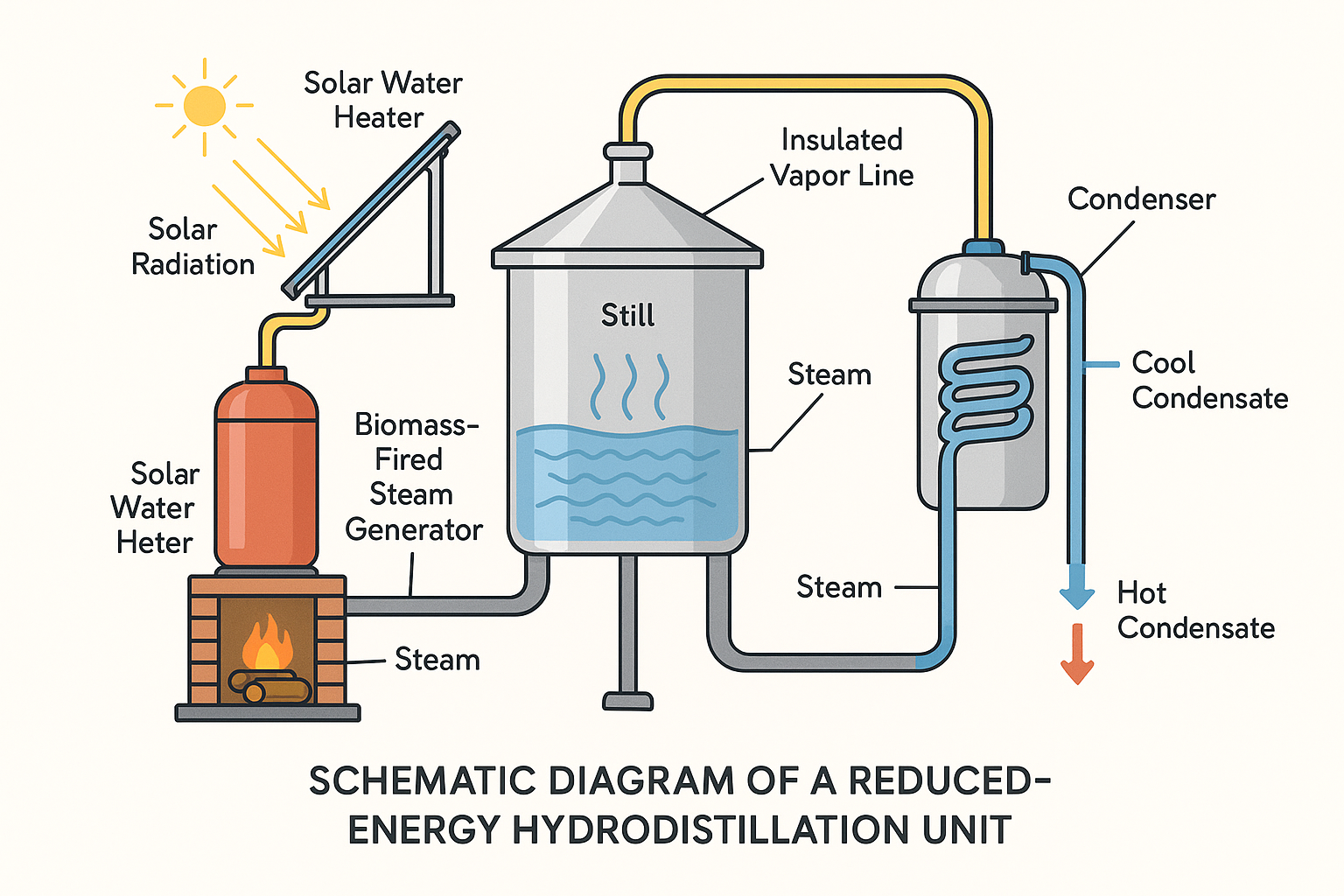

1. Insulated Distillation Units

- Insulate the boiling chamber and vapor line with materials like ceramic fiber, rock wool, or reflective foil

- Minimizes heat loss, improving thermal efficiency by 15–30%

- Especially effective in open-fire or LPG-fired setups

2. Condensate Water Reuse System

- Recycle hot condensate water from the condenser into the boiling chamber

- Saves up to 30% fuel energy, as reused water is already near boiling point

- Helps maintain distillation pressure & temperature

3. Low-Pressure Steam Hydrodistillation

- Modify system to operate under low-pressure steam (~1–1.5 atm)

- Shortens extraction time and reduces energy per kg of biomass

- Requires sealed units and pressure control valves

4. Solar-Assisted Hydrodistillation

- Integrate solar water heaters or flat-plate collectors to preheat water or steam

- Reduces LPG/firewood use by 40–60% during daylight operations

- Feasible for community distillation units in tropical zones

5. Biomass-Fired Steam Generators

- Use agro-waste (e.g., agarwood prunings, rice husk, coconut shells) as fuel

- Retrofit your boiler with a gasifier or efficient rocket stove design

- Reduces firewood demand and carbon footprint

6. Batch Time Optimization

- Pre-soak or pre-crush plant material to reduce distillation time by 15–25%

- Apply enzymatic softening (pectinase, cellulase) before distillation to weaken cell walls

7. Coil-in-Coil or Plate Condensers

- Replace old copper pipe condensers with multi-surface stainless coil or plate-type

- Achieve faster and more efficient vapor condensation with less cooling water and time

8. Smart Process Monitoring

- Use temperature sensors and automated shut-off valves to prevent overheating or unnecessary run time

- Real-time monitoring can cut fuel waste by 10–20%

9. Hydrodiffusion + Intermittent Steam Flow (Pulse Mode)

- Pulse-mode steam application with intermittent shutoff cycles allows better oil yield with less continuous energy input

- Especially useful for resinous woods and roots

10. Compact Modular Stills

- Design modular stills (20–50L) for small-batch, targeted distillation

- Heats faster and consumes less fuel per run

- Ideal for community co-op or mobile distillation units

Expected Energy Savings Table

| Strategy | Energy Savings | Notes |

|---|---|---|

| Insulation | 15–30% | Easy retrofit |

| Condensate reuse | 20–30% | Improves cycle time |

| Solar preheat | 40–60% | Daylight only |

| Biomass burner | 50–70% vs. LPG | Eco-friendly |

| Enzyme pre-treatment | 15–25% | Boosts oil recovery, shortens run time |

Recommended Hybrid Setup for Sustainable Operations

For a rural agarwood distillery:

- Solar preheater + biomass-fired boiler (rice husk/coconut shell)

- Fully insulated stainless still (50–100L)

- Enzyme pre-treatment chamber (BioFusion™-ready)

- Condensate reuse & digital temp sensor + manual timer

Up to 60–70% total energy savings